Yenchen will attend ACHEMA 2018(2018/06/11~06/15)

Yenchen will attend ACHEMA on June 11 ~ 15, 2018.

Yenchen Machinery Co., Ltd. has been specializing in manufacturing Pharmaceutical Machine for many years.

We mainly provide Pellet Machine, Coating Machine, Extraction Machine, Sterilizer and Ointment Equipment which can be widely applied to Pharmaceutical, Food and Chemical Industry.

In addition, our main products also include High Shear Mixer, Fluid Bed Dryer, Oral Dosage Equipment and Dry Granulator.

As a leading manufacturer of Pharmaceutical Machine, we offer above mentioned products with superior quality.

Exhibition Detail

- ACHEMA – World Forum and Leading Show for the Process Industries

- Date: June 11 to 15, 2018

- Show Hours: Monday - Thursday: 9 am - 6 pm / Friday: 9 am - 4 pm

- Venue: Exhibition Centre Frankfurt

- Our Booth: Hall 3.1, B4

Display Products

|

Fluid Bed Dryer, Granulator, Coater |

|---|---|

| Model Number: FBDD-3BG | |

| Product Page Send Inquiry Reservation | |

|

Functions: 1. Drying: Wet powder or granules drying 2. Top Spray: Spray binder on powder for granulation 3. Bottom Spray: Pellet Suspension Coating or Film Coating, Enteric Coating 4. Side Spray: Pellet Powder Coating, Suspension Coating or Film Coating, Enteric Coating 5. (Aqueous or organic solvent are applicable) 1. Top Spray: 1-1.Pharmaceutical: For medicines, biopharmaceutical, and Chinese medicine’s granulation or drying 1-2.Food: Instant food, juice powder, seasoning, food additive, lactic acid bacteria’s granulation or drying 2.Bottom & Side Spray: Medicines and healthy food for a controlled release of active ingredients |

|

|

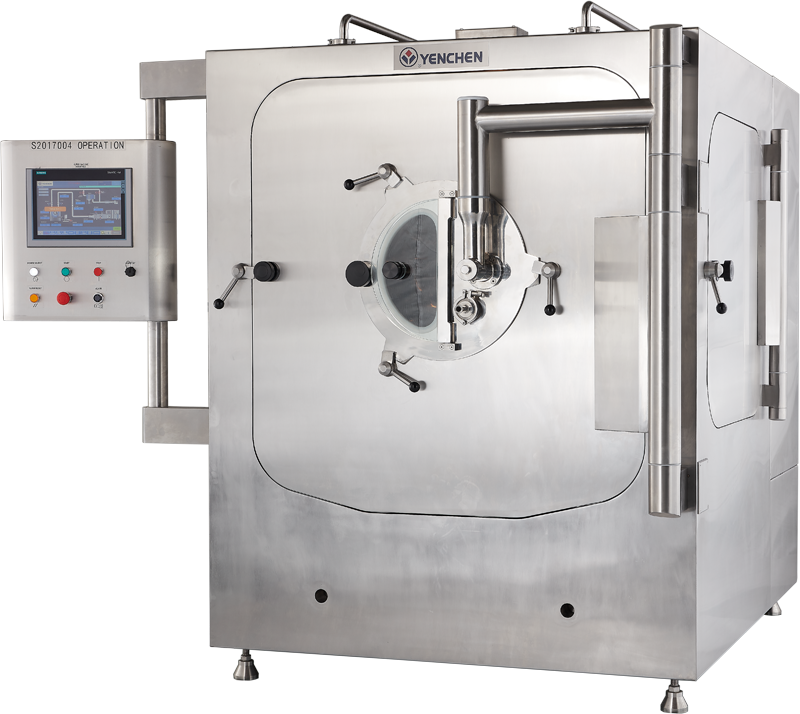

Tablet Coating Machine |

| Model Number: SC-C100F | |

| Product Page Send Inquiry Reservation | |

| Functions: 1. Film Coating: Coat with a uniform and a thin protection layer on he tables. (Aqueous or organic solvent are applicable) 2. Enteric Coating: Coat with a uniform protection layer on the tablets to against the gastric acidity. 3. Sugar Coating: Coat with sugar protection layers on the tablets. Applications: 1. Pharmaceutical: For tablets film coating, enteric coating, sugar coating and control released coating. 2. Food: Film coating of the agriculture product and healthy food, sugar coating of chewing gum and candy. 3. Seed: For insect protection layer or nutrient. |

|

|

Roller Compactor |

| Model Number: RC-R | |

| Product Page Send Inquiry Reservation | |

| Functions: 1. Regulatory compliance : cGMP, PIC/S, 21 CFR part11. 2. Turnkey design : The roller compactor is designed with 3 functions, which are "compression", "cutting", and "granulation". 3. Flexible adjustment : Hydraulic pressure is adjustable to accommodate wide range of materials. Powder feeding screw and roller speed can be adjusted with variable speeds. 4. Cooling function : The connection of a cooling system to the bottom of the hopper can reduce the high temperature generated during operation to ensure product quality. 5. Closed-system design : Dust does not leak during production. 6. Utility model patent : Powder feeding screw, roller, cutting roller, granulation claw, granulation screen can be fast installed and removed.(Patent no.: M479160) 7. Easy to clean : Inside of machine can be washed directly with water to improve clean efficiency. 8. Without water in the granulation process : Procducts which are sensitive to water, light bulk density, or poor flow ability can reach a stable result by applying the dry granulation process. 9. Process transparency : Producton prcess can be clearly inspected by the large sight windows. Application: 1. Pharmaceutical 2. Biotech products 3. Chemical Industry 4. Agricutural products 5. Food Industry 6. Electrical, Mechanical and other industry 7. Pigment |

Contact us If you want to visit our booth , plesase contact us.

We will cordially welcome you.

Please fill in the form below, we will get back to you as soon as possible.

You could see more information from the offical web site of ACHEMA – World Forum and Leading Show for the Process Industries

You could see more photos from the fllickr website.

Yenchen will attend ACHEMA 2018(2018/06/11~06/15) | Tablet & Sterilization Machines - Pharmaceutical Manufacturing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 57 years of experience, Yenchen ensures each customer's demands are met.