High Shear Mixer Granulator

SMG

Super Mixer Granulator

High Shear Mixer Granulator has unique design and function. In the cone-shaped vessel, the main impeller mixes the powder into fluidized vortex and forms agglomerates with the binder solution. Then the high speed chopper breaks the agglomerate into granules by a high speed rolling action. It not only effectively realizes the mixing of powder and adhesive, but also ensures the particle uniformity of the final product, improving production efficiency and product quality.

Functions

1. Mixing: Powder and powder

2. Granulation: Powder and binder

Description of the process

1. By using vacuum system or lifting system to transfer powder from an IBC (Intermediate Bulk Container) into the mixing bowl.

2. Serveral kinds of powder can be uniformly mixed by using the main impeller.

3. Binder (solution) can be sprayed from pressure tank (or solution tank) to powder by the spray nozzle.

4. Then the high-speed chopper breaks the agglomerates into granules.

5. Finished wet granules will be discharged from discharge valve.

(The finished wet granules can be also transferred to a container of Fluid Bed Dryer via an in-line mill.)

Features

1. Follows the regulations of cGMP, PIC/S GMP, FDA.

2. High uniformity of mixing: Even with big difference of bulk density of powder still can mix very well. Binder (solution) can be sprayed from pressure tank (or solution tank) to powder by the spray nozzle.

3. High Shear Mixer Operates just in Short mixing time.

3a. Dry mixing: 2~5 minutes.

3b. Granulation: 5~10 minutes.

4. Multi-safety Interlock System:

4a. Stop operation when the cover is not closed properly.

4b. Stop operation when the cover of discharge valve is not closed properly.

4c. Stop operation when the air pressure is not sufficient for the seal.

5. Separated compressed air routes of the High Shear Mixer is especially designed to meet the good air quality: the compressed air for air seal will pass through an air filter. For the cylinder, the compressed air will pass through lubricating oil to ensure the air quality and lubrication.

6. Equipped with unique design of the air seal: This design can prevent powder access into the main seal and the chopper to prevent powder dropping.

7. The clearance between impeller and the bottom of mixing bowl is only about 0.5~0.8 mm; therefore, high mixing efficiency can be achieved.

8. Clamps of the cover: special designed by an eccentric wheel of clamps for easy operation and well sealed.

Specification Sheet

| MODEL | FULL CAPACITY | WORKING CAPACITY | WORKING BATCH (BD = 0.5G/C.C.) | MAIN DRIVE (60HZ) | MAIN DRIVE (60HZ) | CHOPPER DRIVE (60HZ) | CHOPPER DRIVE (60HZ) | NET WEIGHT | DIMENSION |

|---|---|---|---|---|---|---|---|---|---|

| L | L | Kg/Batch | Kw | rpm | Kw | rpm | Kg | L x W x H (mm) | |

| YC-SMG-20 | 20 | 7~14 | 4~7 | 2.5 | 172 | 0.75 | 3440 | 200 | 1560 x 540 x 1500 |

| YC-SMG-100 | 100 | 35~70 | 18~35 | 5.5 | 172 | 2.2 | 3440 | 850 | 2100 x 700 x 2000 |

| YC-SMG-150 | 150 | 53~105 | 26~53 | 11.2 | 172 | 3.7 | 3440 | 1000 | 2300 x 850 x 2500 |

| YC-SMG-250 | 250 | 88~175 | 44~88 | 15 | 172 | 5.5 | 3440 | 1500 | 2420 x 900 x 2500 |

| YC-SMG-300 | 300 | 105~210 | 53~105 | 22.5 | 160 | 5.5 | 3440 | 1900 | 2600 x 950 x 2500 |

| YC-SMG-400 | 400 | 140~280 | 70~140 | 26.5 | 145 | 7.3 | 3440 | 2500 | 2800 x 2700 x 3200 |

| YC-SMG-600 | 600 | 210~420 | 105~210 | 37 | 120 | 11.2 | 3440 | 3100 | 3000 x 3000 x 3500 |

| YC-SMG-800 | 800 | 280~560 | 140~280 | 56 | 120 | 15 | 3440 | 3500 | 3150 x 4000 x 3500 |

| YC-SMG-1000 | 1000 | 350~700 | 175~350 | 75 | 180 | 22.5 | 3440 | 3800 | 3350 x 4000 x 4000 |

| YC-SMG-2000 | 2000 | 700~1400 | 350~700 | 132 | 145 | 37.5 | 3440 | 4800 | 4000 x 4000 x 4500 |

Applications

- Pharmaceutical: Powder mixing, granulating with binder before tableting.

- Food: Fruit favored tablet, seasoning and healthy food granulation.

- Chemical material mixing and granulation.

- Electronic material mixing and granulation.

Laboratory Equipments

Laboratory Models: SMG-3, SMG-5, SMG-10, SMG-20

Laboratory Multi-bowl Model: SMG-3/2/1, SMG-10/5, SMG-20/10

Optional devices are available

1. Solution spray system: by using pressure or pump to transfer

2. Human-Machine Interface (HMI) design

3. The end point control of granlation: by ampere or lorque

4. Explosion Proof Device: for organic solvent

5. Jacket: for cooling or heating

6. Discharge with Cone Mill, and can be connected to the Fluid Bed Dryer

7. Material transfer: by vacuum suction or lifting system

8. WIP system

9. Main Impeller Lifting System for cleaning

10. Preparation Tank

Gallery

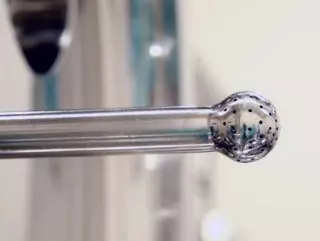

- SMG close-up

- SMG Chopper

- SMG-WIP

- SMGD + Cone Mill

- Bucket cover clamp

- SMG window with scraper

- SMG interior

- Files Download

High Shear Mixer | Pharmaceutical Manufacturing & Processing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, High Shear Mixer Granulator, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 57 years of experience, Yenchen ensures each customer's demands are met.