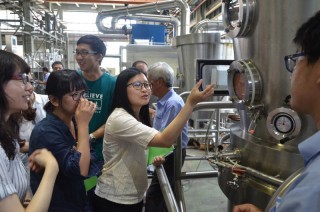

Welcome Food and Drug Administration to Yenchen

Food and Drug Administration (TFDA) came to Yenchen Machinery for GMP training, and was lectured by the chairman, vice manager Mr. Wu, and deputy manager Mr. Shen of Yenchen on September 5, 2017.

- Products

Fluid Bed Dryer / Granulator / Coater

FBDD-B/G

Fluid Bed Dryer / Granulator / Coater(double shaking) is a multi-functional machine that combines drying, top spray granulation, bottom spray coating and side...

DetailsTablet Coating Machine

SC

Tablet coating machine forms a thin film protective layer on the surface of tablets, protecting drugs from external environmental influences and extending...

DetailsHigh Shear Mixer Granulator

SMG

High Shear Mixer Granulator has unique design and function. In the cone-shaped vessel, the main impeller mixes the powder into fluidized vortex and forms...

Details

Welcome Food and Drug Administration to Yenchen | Tablet & Sterilization Machines - Pharmaceutical Manufacturing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 57 years of experience, Yenchen ensures each customer's demands are met.