The Ten Critical Parameters for Aqueous Coating

Source : Yenchen Technical Process Consultant, Dr. Fred Rowley

1. Solution Preparation and Holding Practices

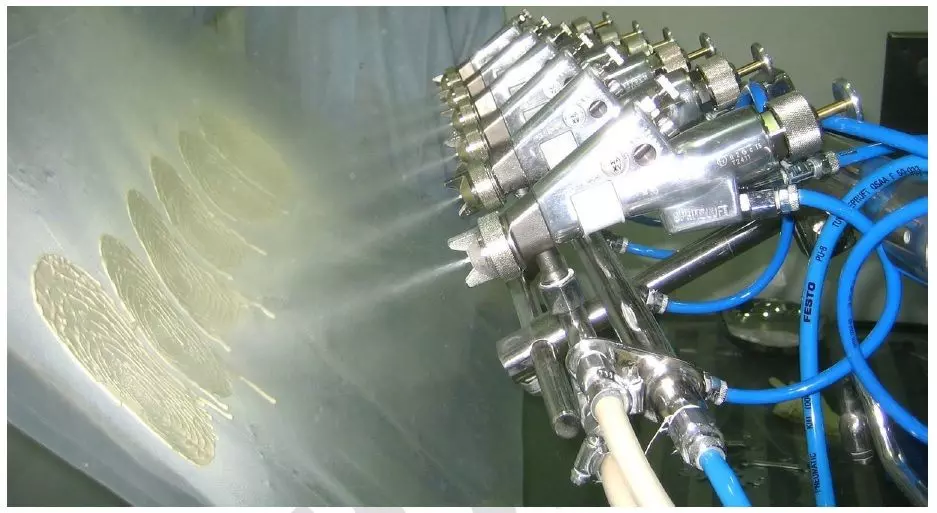

2. Pan Capacity, and how you use it or misuse it

3. Gun Geometry

4. Atomizing / Pattern Air

5. Pan Pressure

6. Pan Speed

7. Spray Rate

8. Inlet / Outlet Air temperature

9. Total Aire Volume

10. Adhesion of particles to the gun surface

If you have any technical questions, please contact with Grace Chiang Email:grace.chiang@yenchen.com.tw

Copyright © 2019 YENCHEN MACHINERY CO., LTD. All Rights Reserved.