Bottom Spray Technology

Source : Yenchen Technical Process Consultant, Dr. Fred Rowley

What Exactly Is A Bottom Spray and Why Is It Used?

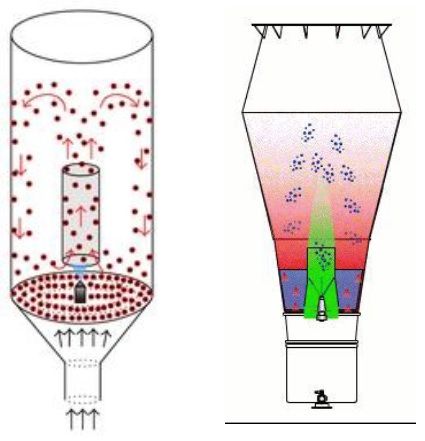

- It is a closed, partitioned processing chamber. It shares common features found on a fluidized bed granulator/dryer.

- It is the only technology today that utilizes a "bottom spray".

- It is used to primarily to coat pellets and spheres with extreme precision.

- More widely used in non-pharmaceuticals.

- Particle transport in precision coating.

In Pharmaceuticals we often think that equipment was invented for our industry. Most of the time the exact opposite is true, we borrow equipment from other industries and adopt it for our use. The Wurster is an unusual case. It was invented to coat tablets, it was later found to be one of the very best technologies to coat seeds (as in plant seeds), beads and fine powders and it is used more in the heavy metals business and seed coating business than in Pharmaceuticals.

Bottom Spray Pellet Coater

- The bottom spray pellet coater is actually a derivative of a circular fluid bed system and a spouted system with the characteristic partition (column) in a lower central part of the process chamber.

- Flow of the pellet coating is significantly different in different areas of the processing chamber.

- The most important area for the coating process is the central partition with the spray nozzle positioned at the bottom of the chamber, where pellets are conveyed pneumatically in a vertical direction.

If you have any technical questions, please contact with Grace Chiang

Email:grace.chiang@yenchen.com.tw

Copyright © 2019 YENCHEN MACHINERY CO., LTD. All Rights Reserved.