Granulation

Source : Yenchen Technical Process Consultant, Dr. Fred Rowley

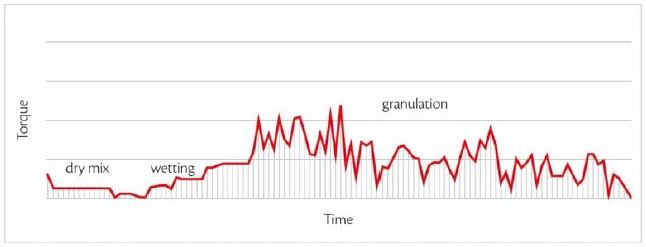

The Curve Doesn't Tell The Whole Story

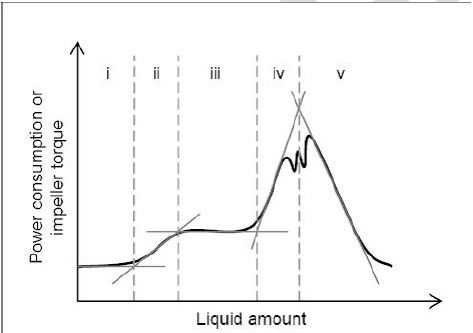

We Begin By Discussing The Curve

- i = Mixing dry powder

- ii = Adding the granulating solution (Binder).

- iii = The period after the binder is added but before resistance begins.

Resistance is linked to binder/powder fusion. - iv = Resistance builds as more and more granules are formed from the binder/powder fusion.

- v = End of granule growth.

High Shear Wet Granulating: The "Rules" or Critical Operating Parameters (This Graph Does Not Address)

A. Method of loading the granulator

B. Fill level (Occupancy)

C. The Nature of the granulating solvent/suspension

D. The method of adding the granulating solution

E. Impeller speed

F. Chopper speed, use of the chopper

G. Post addition granulating time

H. Method of unloading the granulator

I. Scraping down the vessel

➢ A. Method of Loading the Granulator

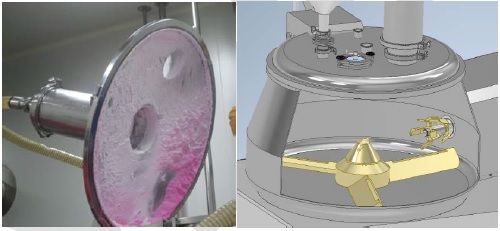

- Because there is limited vertical mixing, what goes in first tends to stay at the bottom of the vessel.

- What goes in last, tends to stay at the top of the vessel (or stick on the lid, see below).

- Layering of key materials is often done.

Conclusion

- You don't just rely on a gauge.

- If you insist and just rely on a gauge then chances are you are doing something wrong.

- The greater the number of products, the more likely you are doing something wrong.

If you have any technical questions, please contact with Grace Chiang Email:grace.chiang@yenchen.com.tw

Copyright © 2019 YENCHEN MACHINERY CO., LTD. All Rights Reserved.