Steam Sterilizer

SS

Autoclave

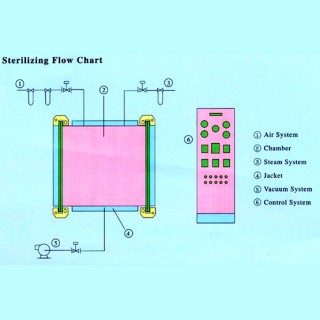

Steam Sterilizer is commonly located between the washing room and sterilization room. The extermination of germs and micro-organisms can be achieved when the object for sterilizing is in the contained sterilization room with an essential high temperature and sufficient time; and therefore safer and more reliable products or instruments can be obtained.

Features

1. Oil hydraulic door: the door clamping device uses an oil hydraulic cylinder to drive clamp for easier and contained operation.

2. Steam piping: steam piping fitting is made of sanitary pipe. The steam passes through one micro pre-filter 1μm

3. Even steam distribution: by vacuum pump and entrance of steam into sterilization room during sterilization to achieve ±1℃ sterilization temperature.

4. Fully automatic control: Adopt PLC control system, when the conditions have been set, the process will be controlled automatically.

5. Temperature recorder: records the temperature progress distribution completely and record pressure changes throughout whole sterilization process.

6. Inspection hole: validation testing holes are available for inspection.

7. Computerized Operation: the computer can calculate the FO figure and shows that there is no more than one germ alive in one million of sterilized objects.

8. Three functions in one: integrated sterilization, cooling and leakage test to save time, energy, space and labor.

9. Provide complete original record of sensors and calibration of all instruments.

Specification Sheet

| Model | Volume | Chamber Size | Basic Machine Dimensions | Steam Consumption | Vocuum Pump | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Liter | W | H | D | W | H | D | Kg/Hr | HP | kg | |

| YC-SS-A | 96 | 400 | 400 | 600 | 700 | 1300 | 900 | 60 | 1 | 1000 |

| YC-SS-B | 360 | 600 | 600 | 1000 | 1000 | 1300 | 1300 | 100 | 2 | 1500 |

| YC-SS-D | 800 | 800 | 1000 | 1000 | 1200 | 1700 | 1300 | 130 | 3 | 2000 |

| YC-SS-1B | 1440 | 1000 | 1200 | 1200 | 1400 | 1900 | 1500 | 200 | 3 | 3000 |

| YC-SS-1D | 2400 | 1000 | 1200 | 2000 | 1400 | 1900 | 2300 | 280 | 5 | 4000 |

| YC-SS-2A | 1872 | 1200 | 1300 | 1200 | 1600 | 2050 | 1500 | 240 | 3 | 3500 |

| YC-SS-2C | 3120 | 1200 | 1300 | 2000 | 1600 | 2050 | 2300 | 350 | 7½ | 5000 |

| YC-SS-3 | 2680 | 1400 | 1600 | 1200 | 2000 | 2350 | 1500 | 310 | 5 | 4500 |

| YC-SS-4C | 4480 | 1400 | 1600 | 2000 | 2000 | 2350 | 2300 | 415 | 10 | 6000 |

| YC-SS-8A | 8060 | 1400 | 1600 | 3600 | 2000 | 2350 | 3900 | 630 | 15 | 9000 |

*YC-SS Model for Steam Sterillizer; YC-EOG Model for E.O. Gas Sterilizer.

* Specifications subject to change without notice.

Applications

Pharmaceutical, Food, Hospital, Research Laboratory.

- Files Download

Tags

Steam Sterilizer | Pharmaceutical Manufacturing & Processing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, Steam Sterilizer, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 59 years of experience, Yenchen ensures each customer's demands are met.