The Fourteen Root Causes of Tablet Sticking and Picking

Source : Yenchen Technical Process Consultant, Dr. Fred Rowley

1. The powder blend is too wet or there are residual pockets of moisture.

2. The active ingredient (API) attracts moisture: hygroscopic or highly water soluble.

• The active ingredient attracts moisture from the excipients then changes.

3. The punches have not completely dried after cleaning.

4. The punch surface is too porous for the material you are compressing.

5. One or more of the components in the formula have melted.

• Low glass transition temperature

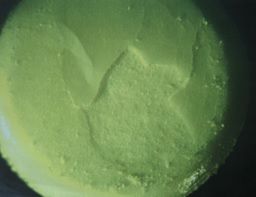

6. The powder blend (API) attacks the punch tip.

7. Insufficient lubrication in the formula

8. The lubricant was poorly blended, poorly screened or both.

9. Tooling issues:

• Poor maintenance and preparation

• Punch Tip Cup (lack of Bakelite relief?)

• Cup or logo depth (letters/numbers too narrow and/or too deep)

• Punch Head Design

• Uneven coating on the tip

10. Ejection issue disguised as a picking issue.

11. Heated punches (poor oil lubrication/tooling tolerances/seals/pins)

12. Inappropriate pre-compression setting

13. Wrong press speed

14. Room conditions

If you have any technical questions, please contact with Grace Chiang Email:grace.chiang@yenchen.com.tw