Is Pre-Compression Tablet Thickness A True Critical Operating Parameter? -1

Source : Yenchen Technical Process Consultant, Dr. Fred Rowley

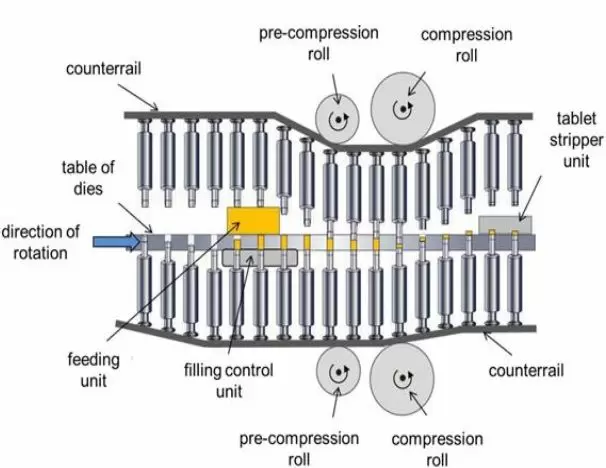

Photo 1: A pre-compression thickness setting on a 1980 tablet press. Note that the label states "tamping".

What exactly is a tamp, anyway? A tamp is a device used to compact or flatten an aggregate or powdered / granular material, typically to make it resistant to further compression or simply to increase its density. In many countries the term is also described as pre-compression tablet thickness for clear understanding.

Note the language used in a typical operation manual:

"Pre-compression is the preliminary compression force that tablet presses apply prior to the main compression. Operators often unknowingly set compression levels improperly, utilizing a percentage of the final compressive force, and this isn't a recommended practice. Precision in pre-compression is crucial.

If an operator applies excess pre-compression, chances increase that tablets will fracture. On the other hand, if operators do not apply sufficient pre-compression, there will be increased air entrapment in the formulation. In the presence of fractures, the top of a pre-compression tablet, or its cap, may break away from its main body. This occurrence is tablet capping, and it most often happens as a result of trapped air in the powder material during pre-compression."

If you have any technical questions, please contact with Grace Chiang Email:grace.chiang@yenchen.com.tw

Copyright © 2019 YENCHEN MACHINERY CO., LTD. All Rights Reserved.