Automatic Tablet & Capsule Inspection Machine

SELMA

Tablet & Capsule Vision Inspection Machine

SELMA series is vision inspection machine that can easily detect external defect of tablet & capsule by cameras and inspection algorithm.

This ultimate high-tech machine can inspect even the small defect by high-degree camera resolution.

Also anyone can operate the machine simply by compact design and easy-handle User Interface.

Agent for Taiwan market only

It delivers same inspection quality as that respective detection of tablets and capsules defects through the system setting and applying the best algorithm as well without structural change or complicated settings.

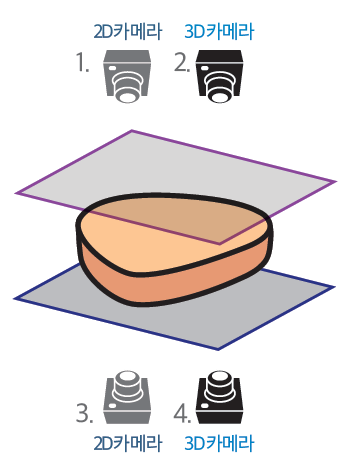

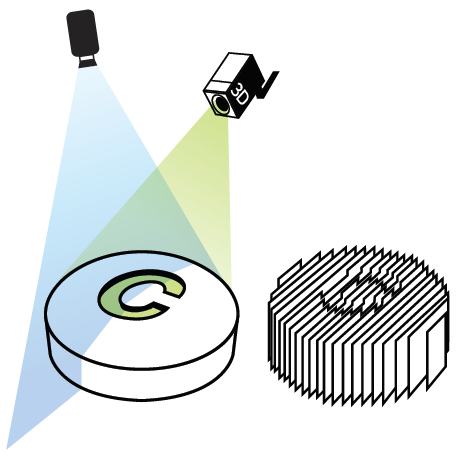

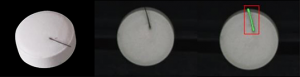

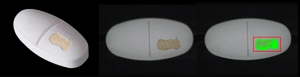

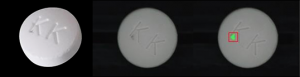

Camera System - Tablet Inspection

Top/Bottom

Double inspection by 3D camera (2 Nos.) & 2D color camera (2 Nos.)

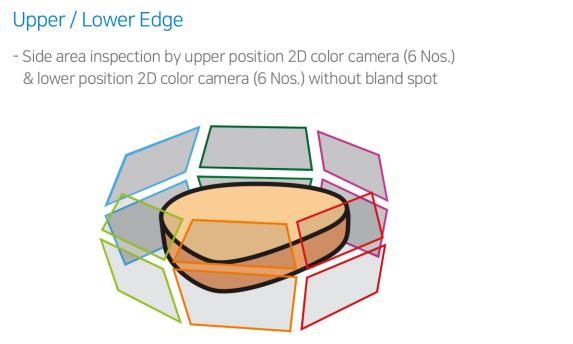

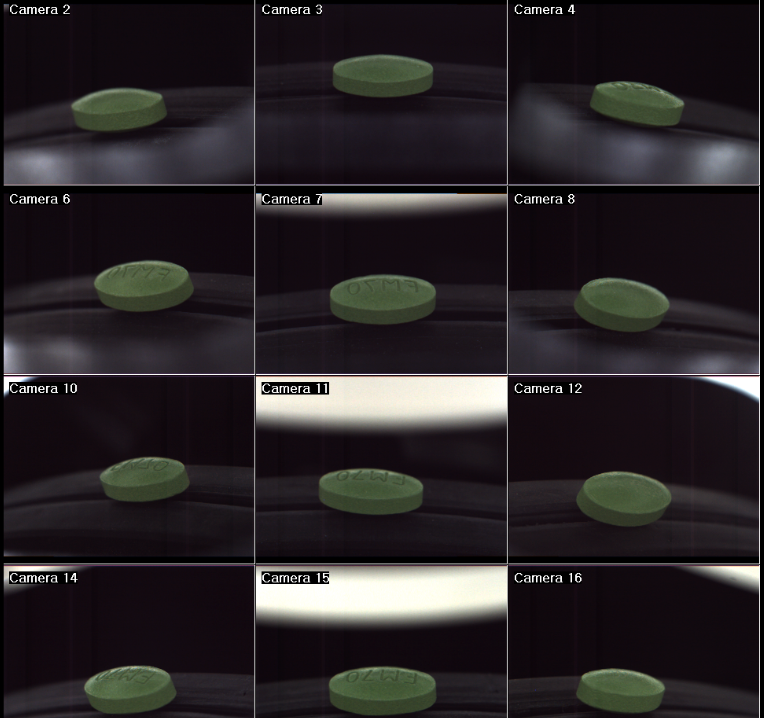

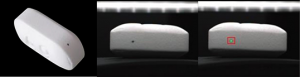

Side

Side area inspection by upper position 2D color camera (6 Nos.) & lower position 2D color camera (6 Nos.) without bland spot.

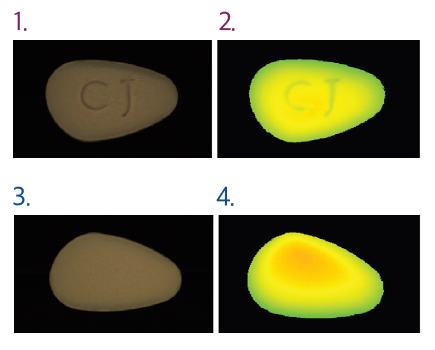

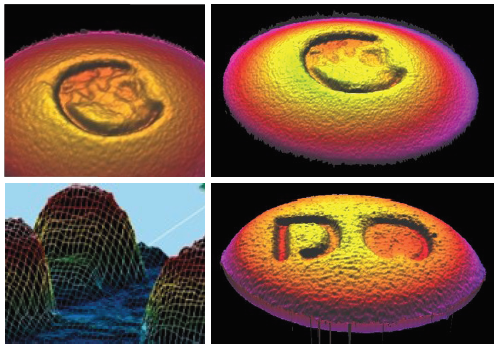

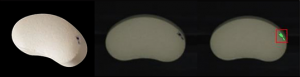

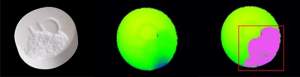

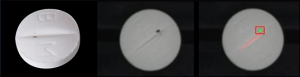

3D camera Inspection

2D image is hard to check the depth-defect such as engraving error, poor coating on surface.

3D image can accurately check the depth-defect by laser scanning.

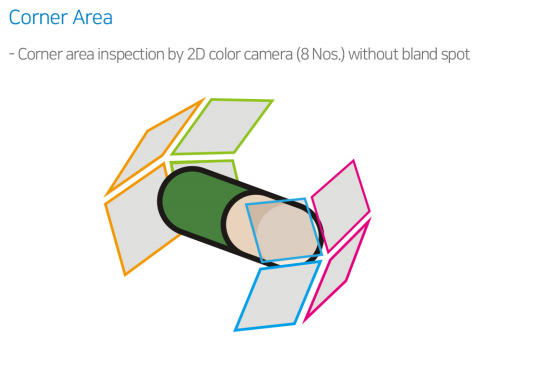

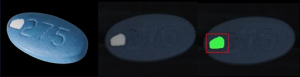

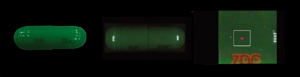

Camera System - Capsule

Corner

Coner area inspection by 2D color camera (8 Nos.) without bland spot.

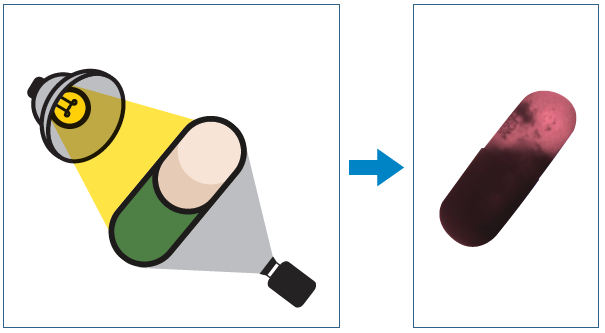

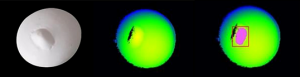

Powder Volume

IR camera (1 No.) scans through inside of capsule, calculates the powder volume percent (%)

(Able to inspect the black color capsule)

Specification Sheet

| Inspection Function | Applicable Type | – Tablet : Uncoated, Film-coated, Sugar-coated, etc – Capsule : Hard capsule, etc | |

| Applicable Size | SELMA series | Length : 5~24mm Width(dia) : 5-12mm Height : 2~8mm | |

| Inspection Item | Tablet : Spot, Scratch, Crack, Chip, Foreign particle, Miss print, Poor mark, Different color, Dirt, Depth error, Bad coating, etc Capsule : Spot on body, Joint defect, Hole on cap, Empty capsule, Dent, Missing letter, Spot on corner, etc | ||

| Machinary Part | Camera (SELMA200) | T-type | 2D : 14 Nos 3D : 2 Nos |

| C-type | 2D : 15 Nos | ||

| H-type | 2D : 15 Nos 3D : 2 Nos | ||

| Electric Power | 220V/380V/415V/440V ± 10%, 50/60 Hz | ||

| Compressed air(dry) | 5~8 bar | ||

| Environment | Material | SUS304, SUS316, UPE | |

| Pneumatic pressure | ≥0.35MPa | ||

| Temperature Humidity | 10~30°C / 30~70% | ||

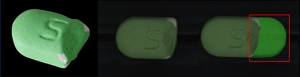

Defect Type (Tablet)

Corner spot |  Spot 3 layer tablet |  Chipped edge coating |

Dark line |  Missing letter |  Chipped top coating |

Spot in engraving |  Chipped edge |  Broken top surface |

Chipped engraving |  Broken |  Broken edge |

Broken |  Stained in engraving |  Chipped top coating |

Spot on side |  Stained |  Abnormal shape |

Capping |  Spot on split line |  Bump |

Crack on side |  Stained engraving |  Chipped in engraving |

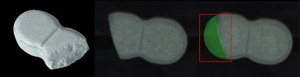

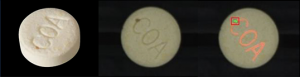

Defect Type (Capsule)

Spot on body |  Joint defect |  Hole on cap |

Empty capsule |  Dent |  Dent |

Missing letter |  Spot on cap |  Spot on body |

Hole on body |  Hole on body |  Dent |

Missing letter |  Joint defect |  Spot on corner |

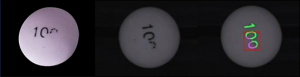

Inspection Item (Tablet)

| Item | Contents |

| Surface | Foreign matters, stains, cracks, dents, discoloration, lifted coating, etc. |

| Printing | Erased printing, blurring, scratches, missing printing, etc |

| Engraving | Sticking, different engraving, double engraving etc. |

Inspection Item (Capsule)

| Item | Contents |

| Surface | Surface stains, color defects, discoloration, differences in color, foreign matters, foreign fragments, dents, rips, empty capsules, etc. |

| Printing | Print stains, smears, errors in printed letters, etc. |

- Movies

- Related Products

UV Laser Printer

QUALIS-UVS

The QUALIS-UVS laser printer imprints on tablets at a speed up to 400,000 per hour, making...

DetailsUV Laser Printer for Laboratory

LIS-Labo

The LIS-Labo UV laser printer for laboratories is ideal for small or R&D batches and samples....

DetailsUV Laser Printer

LIS-250D

Without the use of ink, the LIS marks the surface of tablets and softgel capsules. The UV laser...

Details- Files Download

- News

Introduction of Automatic Tablet & Capsule Inspection Machine

Yenchen acts as agent of NFA Automatic Tablet & Capsule Inspection Machine. This Machine is the highly sophisticated equipment that automatically detects...

Automatic Tablet & Capsule Inspection Machine | Pharmaceutical Manufacturing & Processing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, Automatic Tablet & Capsule Inspection Machine, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 59 years of experience, Yenchen ensures each customer's demands are met.