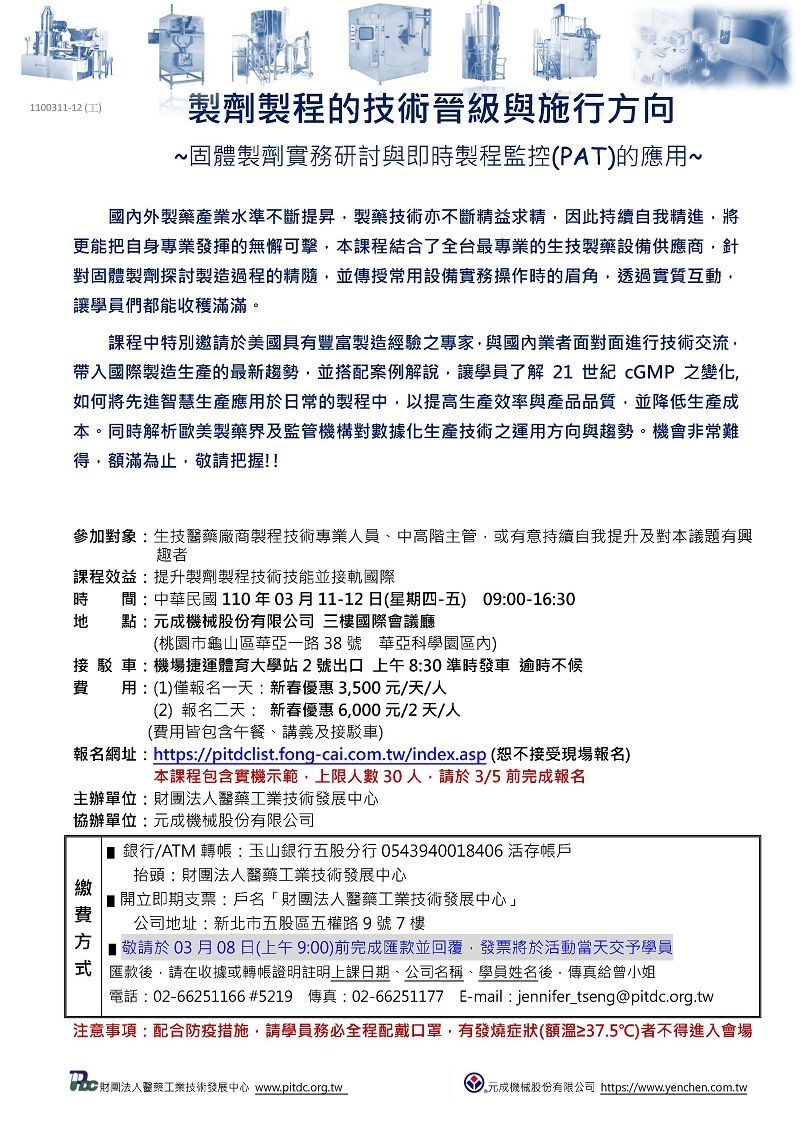

PITDC will hold a seminar in Yenchen Machinery on March 11~12, 2021

PITDC will hold a seminar in Yenchen Machinery on March 11~12, 2021. This course focuses on manufacturing process of solid dosage and common equipment practical operation. In the course, expert with rich manufacturing experience in the United States is specially invited. The lecturer will share the changes of cGMP in the 21st century, how to apply advanced smart production to daily manufacturing processes to improve production efficiency and product quality, and reduce production costs.

[Co-organizer]:Yenchen Machinery Co., Ltd.

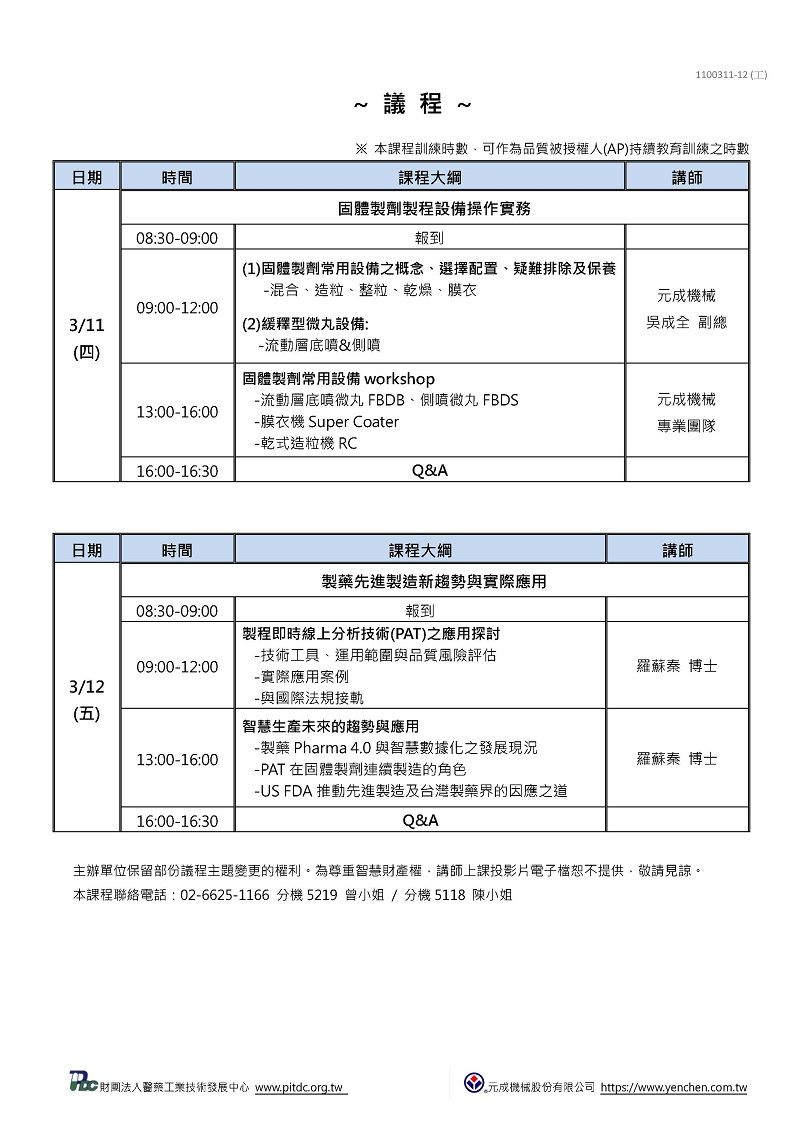

[Event Time]:March 11~12, 2021 AM09:00-PM16:30

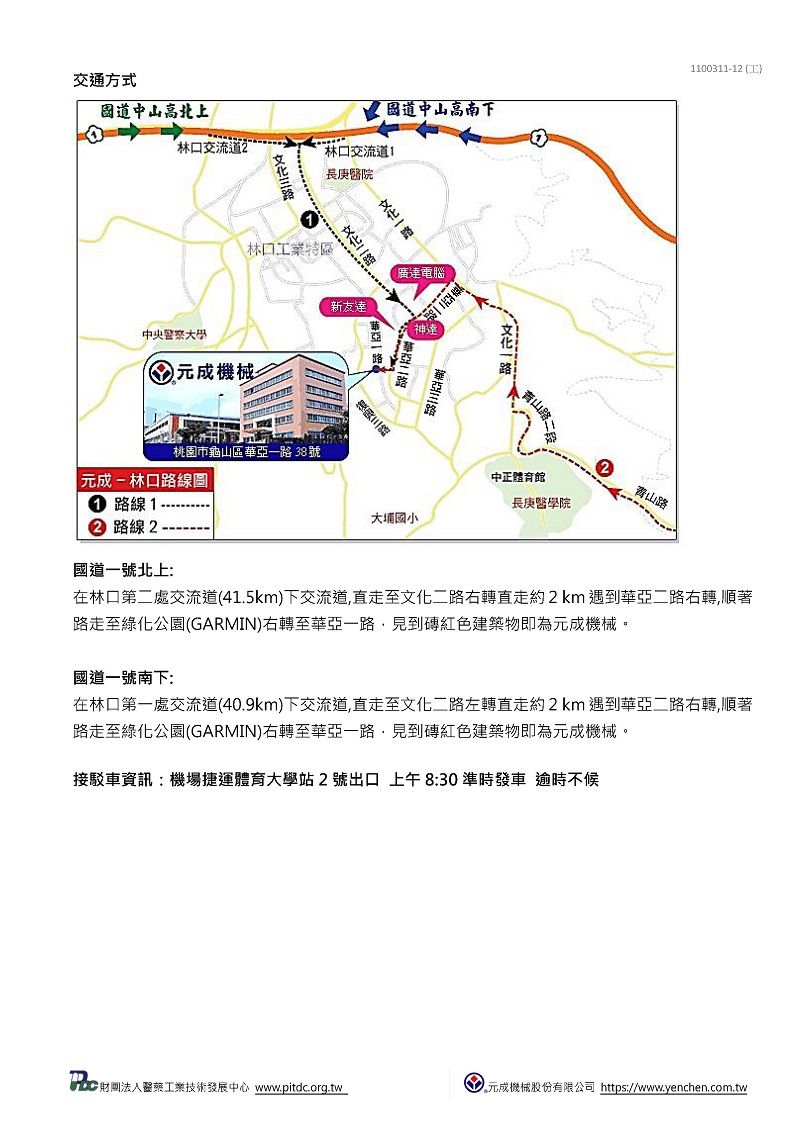

[Event Location]:Yenchen Machine 3F International Conference Hall(Adress: No.38, Huaya 1st Rd., Guishan Dist., Taoyuan City)

[Registration]: Online registration

[Registration fee]:One day: NTD. 3,500 per person; Two days: NTD. 6,000 per person

- Products

-

Fluid Bed Dryer / Spray Granulator

FBDG

Single shaking type of Fluid Bed Dryer and Granulator (FBDG): For this model cannot add bottom spray or side spray. For bottom spray or side spray please...

DetailsFluid Bed Dryer / Granulator / Coater

FBDD-B/G

Fluid Bed Dryer / Granulator / Coater(double shaking) is a multi-functional machine that combines drying, top spray granulation, bottom spray coating and side...

DetailsTablet Coating Machine

SC

Tablet coating machine forms a thin film protective layer on the surface of tablets, protecting drugs from external environmental influences and extending...

DetailsRoller Compactor

RC

Roller Compactor serves as a pivotal solution for dry granulation, particularly benefiting drugs sensitive to moisture and products requiring improved...

Details

PITDC will hold a seminar in Yenchen Machinery on March 11~12, 2021 | Tablet & Sterilization Machines - Pharmaceutical Manufacturing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 59 years of experience, Yenchen ensures each customer's demands are met.