High Shear Mixer Granulator Dryer

SMGD

Super Mixer Granulator Dryer

High Shear Mixer Granulator Dryer offers multiple functions including mixing, granulation, drying and milling. The entire process can be completed with only one machine, saving space and increasing production efficiency, as well as reducing material handling, residue and contamination during the process. The equipment is operated in a sealed area to minimize the risk of contamination.

3. Four in one process to prevent the movement and contamination of the products.

4. Operation in a closed type design to reduce the contamination.

5. Drying temperature: 50~80℃

6. Drying time: Organic solvent is around 1~2 hrs; water is around 2~4 hrs.

7. Variable speed to meet different process: Mixing and granulation by high speed; drying and discharging by low speed.

Mixing and Granulation:

The main impeller mixed the powder into a fluidized vortex and forms agglomerates with the binder solution. Then the high-speed chopper breaks the agglomerates into granules by a rolling action.

Drying (Use vacuum drying system):

The Mixing Tank is heated by the hot water in jacket; the wet granules are rolling slowly and dehydration by vacuum suction to reach to drying efficiency.

Description of the process

Powder Vacuum Loading → Drying Mixing → Binder Spraying → Wet Granulation → Vacuum Drying → Milling → Auto Suction to Bin.

Features

1. Follow the regulations of cGMP, PIC/S GMP, FDA.

2. WIP System is available.

3. Explosion proof system is available: Suitable for organic solvent.

4. Multi-safety interlock system:

a. Stop operation when the cover is not closed properly.

b. Stop operation when the cover of discharge valve is not closed properly.

c. Stop operation when the air pressure is not sufficient for the seal.

5. Separated compressed air routes design to meet the good air quality: The compressed air for air seal will pass through an air filter. For the cylinder, the compressed air will pass through lubricating oil to ensure the air quality and lubrication.

6. Unique design of the air seal: This design can prevent powder access into the main seal and the chopper to prevent powder dropping.

7. The clearance between impeller and the bottom of mixing bowl is only about 0.5~0.8 mm; therefore, high mixing efficiency can be achieved.

Specification Sheet

| Model | Full capacity | Working capacity | Main drive (60HZ) | Main drive | Chopper drive | Chopper drive (60HZ) | Average working batch (assuming) 0.5G/C.C. | Vacuum pump | Net weight | Dimension |

|---|---|---|---|---|---|---|---|---|---|---|

| L | L | Kw | rpm | Kw | rpm | Kg | Kw | Kg | L x W x H (mm) | |

| YC-SMGD-20 | 20 | 14 | 2.2 | 50 ~ 172 | 0.75 | 300 ~ 3440 | 4 ~ 6 | 2.2 | 300 | 1560 x 540 x 1500 |

| YC-SMGD-100 | 100 | 70 | 3.7 / 5.5 | 172 / 120 | 1.5 / 2.2 | 1720 / 3440 | 25 - 35 | 3.7 | 1000 | 2100 x 700 x 2000 |

| YC-SMGD-150 | 150 | 105 | 7.5 / 11.2 | 172 / 120 | 2.2 / 3.7 | 1720 / 3440 | 35 - 50 | 3.7 | 1200 | 2300 x 850 x 2500 |

| YC-SMGD-250 | 250 | 175 | 11.2 / 15 | 172 / 120 | 3.7 / 5.5 | 1720 / 3440 | 68 - 85 | 5.5 | 1700 | 2420 x 900 x 2500 |

| YC-SMGD-300 | 300 | 210 | 15 / 22.5 | 160 / 105 | 3.7 / 5.5 | 1720 / 3440 | 75 - 105 | 5.5 | 2100 | 2600 x 950 x 2500 |

| YC-SMGD-400 | 400 | 280 | 22.5 / 26.5 | 145 / 95 | 5.5 / 7.3 | 1720 / 3440 | 100 - 150 | 7.5 | 2800 | 2800 x 2700 x 3200 |

| YC-SMGD-600 | 600 | 420 | 37 | 120 | 11.2 | 1720 / 3440 | 150 - 200 | 11 | 3400 | 3000 x 3000 x 3000 |

| YC-SMGD-800 | 800 | 560 | 45 | 120 | 15 | 3440 | 200 - 300 | 15 | 3900 | 3150 x 2800 x 3500 |

| YC-SMGD-1000 | 1000 | 700 | 56 | 80 | 18.5 | 3440 | 250 - 300 | 19 | 4200 | 3300 x 2800 x 4000 |

| YC-SMGD-2000 | 2000 | 1400 | 112 | 80 | 22 | 3440 | 500 - 700 | 37.5 | 5400 | 4000 x 3400 x 4500 |

* Specifications subject to change without notice.

Applications

1. Pharmaceutical: Powder mixing, granulating with binder before tableting.

2. Food: Fruit favored tablet, seasoning and healthy food granulation.

3. Chemical material mixing and granulation.

4. Electronic material mixing and granulation.

Automatic / Closed type operation

1. Powder Vacuum Loading is available.

2. Binder Spraying: Using the mist nozzle design.

3. Touch Screen Interface control system: all the paraeters can be memorable, multilever of pins can be set, connect to the diagrams printing.

4. Discharge connects a Cone Mill and a Bin are available.

5. The end point control of granulation: by ampere or torque.

Gallery

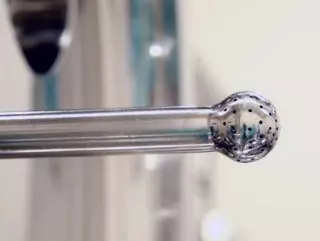

- SMG close-up

- SMG Chopper

- SMG-WIP

- SMGD + Cone Mill

- Bucket cover clamp

- SMG window with scraper

- SMG interior

- Files Download

Super Mixer / Granulator / Dryer | Pharmaceutical Manufacturing & Processing Equipment | Yenchen

Located in Taiwan since 1967, YENCHEN MACHINERY CO., LTD. has been a pharmaceutical manufacturing equipment supplier in pharmaceutical industry. Their main manufacturing and processing equipment include, High Shear Mixer Granulator Dryer, hot air sterilizers, extrusion machines, tablet coating and compression machines, pellet making machines and oral solid dosage manufacturing equipment, which are sold to over 70 countries meeting international standards.

Yenchen was established in 1967, our products and services are widely used in the pharmaceutical, food, biotechnology, chemical, and cosmetic fields, which include solid dosage line, pellet machine production line, syrup line, injection line, ointment line, extraction & concentration turnkey equipments.

Yenchen has been offering customers high-quality pharmaceutical manufacturing equipment since 1967, both with advanced technology and 58 years of experience, Yenchen ensures each customer's demands are met.